[Process Introduction]

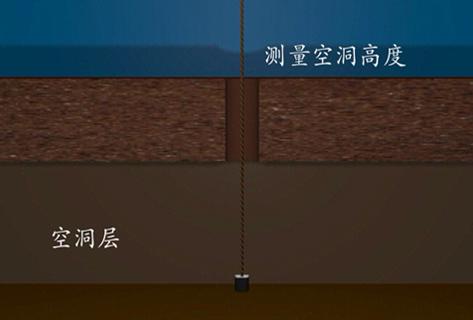

This construction method is suitable for sites with underground goaf, karst caves and other cavities. Based on the characteristics of ground buildings and load requirements, a concrete circular platform is constructed inside the cavity to support the top plate of the cavity. This can effectively solve and prevent the problems of lack of stability, insufficient bearing capacity and collapse in such terrain. Firstly, drill a hole at the top of the cavity with a diameter ranging from 150mm to 200mm; Measure the height of the cavity and blow the bottom of the hole. Secondly, a high-strength non-woven bag with the same geometric dimensions as the platform will be designed and manufactured as a mold and sent into the hole. Transport concrete into a bag through steel pipes, forming a circular concrete load-bearing platform in the cavity. Finally, the top concrete of the bag is repeatedly impacted with steel pipes to tightly bond the platform with the hollow top plate. The diameter of the upper part of the concrete platform can be 800-2000mm.

[Process Characteristics]

1. Quick construction, easy operation, and intuitive quality.

2. Solved the problems of high cost and difficult quality control in traditional filling construction methods such as grouting and concrete filling.

3. Compared with traditional filling treatment methods, construction costs can be saved by more than 60%, and the construction period can be shortened by more than 60%.