[Process Introduction]

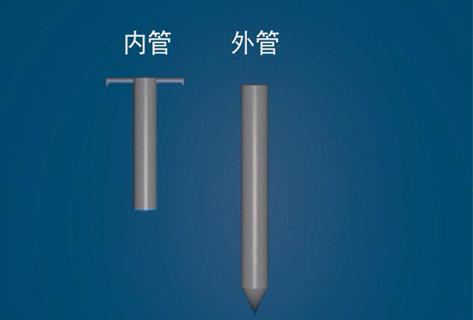

This technology breaks through the current situation where the depth of the hole formed by the immersed tube squeezing equipment cannot exceed 18 meters. It adopts a multi section inner and outer tube combination device, which can increase the depth of the hole formed by the immersed tube several times without changing the original tower foundation, up to a maximum depth of 60 meters. Enable the use of immersed tube compaction method and immersed tube cast-in-place pile in thick backfill and thick self weight collapsible loess sites. The use of this device in the construction of a planar composite foundation on thick backfill and thick self weight collapsible loess sites can achieve a soil compaction degree of 0.93 between piles, and the characteristic bearing capacity of the treated composite foundation can reach 550kpa. Solved the long-standing problem of foundation and foundation construction in thick backfill sites, filling the technical gap in the industry.

[Process Characteristics]

1. The construction depth of immersed tube compacted piles and immersed tube cast-in-place piles can reach 18~60 meters.

2. The construction equipment is easy to operate and the quality is easily guaranteed.

3. Solved the bottleneck problem of various building foundation treatments for thick backfill sites.

4. The application of this method can comprehensively save more than 40% of foundation and foundation construction costs, and the comprehensive construction period can be advanced by more than 50%.