[Process Introduction]

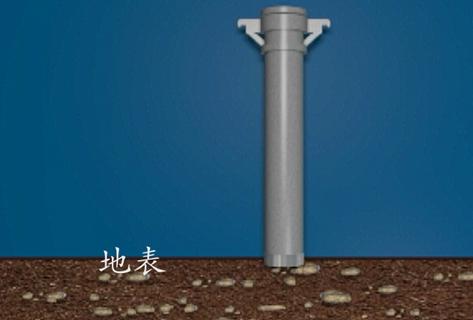

This process is based on the patented equipment of "ramming enlarged head pile", combined with two patented technologies of "external pipe pulling device" and "method of ensuring pile length in gravel layer sand layer", using a company's specially designed external pipe construction with a composite blade ring knife at the bottom end.

[Process Characteristics]

1. This method can penetrate through sand layers, gravel layers, and strongly weathered rocks, providing a new idea and concept for foundation and foundation construction in such geological conditions.

2. After being compacted by sinking the tube, the unevenness of the foundation soil is eliminated, ensuring the safety of the project. The strength of the soil between piles increases by 2-3 times, fully utilizing the high natural bearing capacity of the pebble layer, sand layer, and strongly weathered rock. The characteristic value of the bearing capacity of the processed composite foundation can reach over 600kpa, fully meeting the requirements of high-rise buildings for foundation bearing capacity.

3. Compared with conventional pile types in similar geological structures, this pile type does not require mud or soil transportation on site, and its comprehensive economic indicators are outstanding. Compared with ordinary cast-in-place piles, the construction cost is saved by more than 40% and the construction period is shortened by more than 50%.