[Process Introduction]

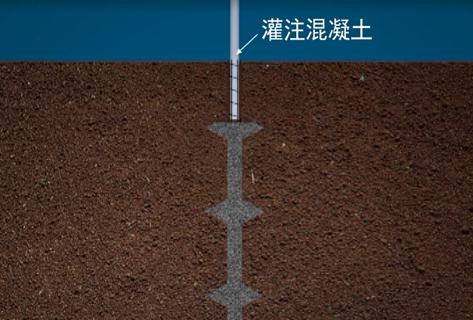

This construction method is based on conventional cast-in-place pile construction, which uses a special device to rotate and expand one or several enlarged disc cavities resembling conical discs at different parts of the pile body. After inserting steel cages and pouring concrete, a pile type is made that is jointly supported by the pile body, bearing disc, and pile root. The position of the bearing plate is determined based on the characteristics of the geological soil, and the construction bearing plate is visible and controllable. The angle between the top and bottom of the load-bearing plate is 70 °, and the diameter of the plate is 2.0~4.0 times the diameter of the pile. The structure of the disc cavity is stable and free of sediment, and the requirement for the thickness of sediment at the pile root is significantly reduced for the bearing capacity of a single pile. Set up bearing discs at appropriate locations on the pile body, and replace the frictional resistance of the pile body with the end bearing capacity of the bearing disc. Within a unit length of the pile body, the bearing capacity can be increased by 30-60 times. Under the same diameter and length as ordinary cast-in-place piles, the single pile bearing capacity is equivalent to 2-3 times that of ordinary cast-in-place piles. This pile type has a more prominent effect on the foundation construction of buildings (structures) with horizontal and pull-out force requirements.

As Wang Mengshu, an academician of the CAE Member, summarized, "DX pile has great environmental, social and economic benefits, changed the stress mechanism of the pile foundation, mobilized the soil bearing capacity of the pile foundation, and has a new idea. This pile type has great promotion value". The coordinated work of multiple plates can form a network stress interval in the foundation soil, with small deformation of the pile foundation, low dispersion of single pile bearing capacity, and high engineering safety.