[Process Introduction]

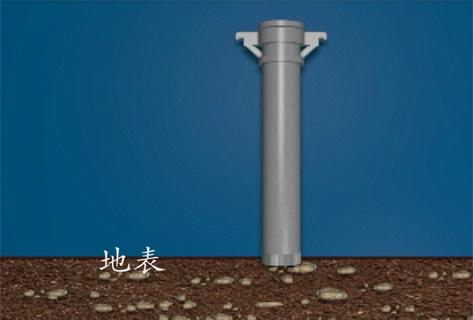

This construction method consists of an outer pipe and an inner rammer. A 400mm thick cast steel head plate is set at the bottom of the outer pipe, and a concrete conveying pipe with a cast steel bottom plate is set on the side wall of the outer pipe, with a diameter of 100mm. The internal rammer adopts a cylindrical shape of 6T~10T and is placed inside the outer pipe hole. The internal rammer impacts the bottom of the outer pipe under the action of gravity, forming a high-energy impact force on the geological soil, and achieving compaction and sinking of the pipe into holes in the soil layer, with a diameter of 500-700mm. When the depth of the immersed tube reaches the design requirements, the concrete is transported while lifting the outer tube. If a steel cage is designed, it can be installed using the post insertion method.

[Process Characteristics]

1. Widely applicable to soil layers, it can form pores in clay, silt, round gravel layer, pebble layer, strongly weathered rock and other soil layers, with a pore depth of over 30 meters.

2. The impact energy of a gravity internal rammer is 3 to 6 times that of a regular diesel hammer.

3. This process can also be used to expand the head at the pile end during construction.